- Services

Technology Capabilities

Technology Capabilities- Product Strategy & Experience DesignDefine software-driven value chains, create purposeful interactions, and develop new segments and offerings

- Digital Business TransformationAdvance your digital transformation journey.

- Intelligence EngineeringLeverage data and AI to transform products, operations, and outcomes.

- Software Product EngineeringCreate high-value products faster with AI-powered and human-driven engineering.

- Technology ModernizationTackle technology modernization with approaches that reduce risk and maximize impact.

- Embedded Engineering & IT/OT TransformationDevelop embedded software and hardware. Build IoT and IT/OT solutions.

- Industries

- GlobalLogic VelocityAI

- Insights

BlogsGlobalLogicJuly 27, 2023Exploring Snowpark and Streamlit for Data Science

I’m Janki Makwana, a Data Scientist at GlobalLogic. I have been working with a major re...

BlogsJuly 18, 2023Manik Jandial

BlogsJuly 18, 2023Manik JandialView on payment industry modernisation: Enablers of change

Welcome to the second part of our two-part series on the evolving payment industry! In ...

- About

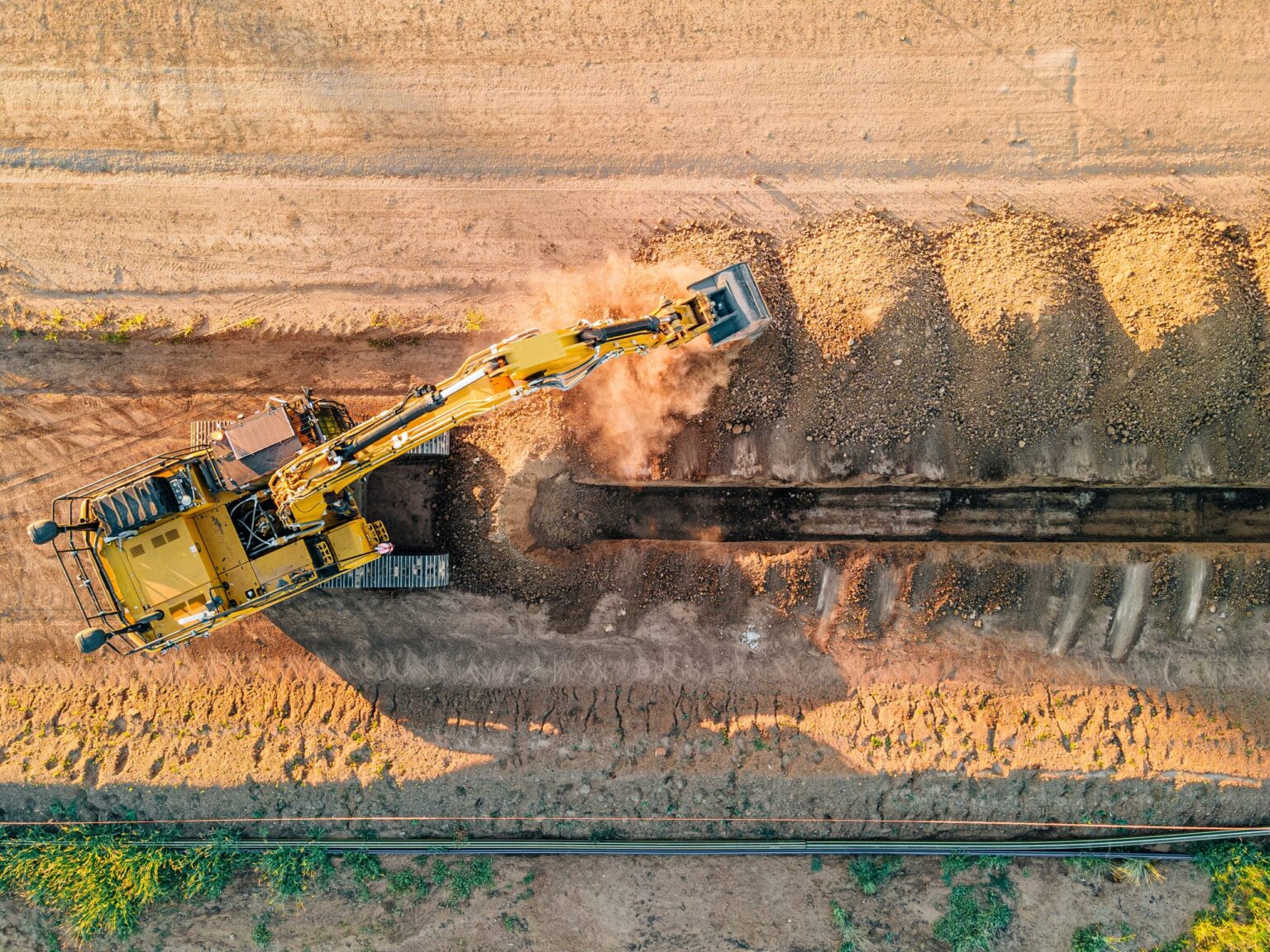

Case StudiesLeveraging the power of IoT with predictive oil monitoring

Share

Our client sits at the centre of building a sustainable energy future

A growing global population continues to drive the need for energy, including oil and gas. At the same time, there is a global transition towards low-carbon energy systems, including wind and solar and new fuel from transport such as advanced biofuels and hydrogen.

Using advance technologies and an innovative approach, our client – a major energy supermajor – is attempting to balance these needs, looking at ways to achieve efficiencies in its current value chain whilst investing in a more sustainable energy future.

Evolving an MVP to a scalable digitally enabled solution

Whenever an industrial machine breaks down, not only there is a loss of productivity, but also expensive unplanned maintenance costs. Understanding the quality of oil used can be a key indicator to the equipment’s health, helping to prevent avoidable equipment failure or deterioration. It also benefits customers by preventing them from discarding good oil before its end of life – saving money and reducing CO2 footprint.

To help their customers better understand the quality of their oil, our client looked to improve the intelligence gained from

oil condition monitoring. More specifically, they wanted to leverage the power of IoT and put real-time insights into the hands of large industrial companies to optimise equipment health, lower maintenance costs, and increase operational efficiency.The conceptual idea was incubated, and an MVP was developed to validate technical feasibility, confirm customer’s willingness to pay and build an investment case. Whilst the MVP was a valuable blueprint, the customer wanted to scale in a cost-effective and timely manner. Our customer was also looking for someone who has experience in developing IoT based software for industrial sector.

The search began in the market to find a new partner who can meet the criterion. GlobalLogic proved to have the right experience, culture, and capabilities to build on the two years of R&D and transition the MVP into a scalable digitally enabled solution.

The Process & Delivery: Giving customers tools to act more sustainably

This app was built for customers, by customers. And what the customers needed was a detailed dashboard that mirrored certain values and parameters relevant to their oil use.

When we took over the project, the MVP presented only a few screens for the customers and lacked flexibility. Our first port of call was to move the basic design to a detailed design, enabling on-site engineers to gain a comprehensive equipment analysis. We designed a scalable navigation system on Azure, keeping in mind that a simple application today would become an integrated platform.

Following a customer-centric approach, we planned, organised, and executed design research activities with customers on every aspect of the UX design. This data was captured through one-on-one interviews and feedback filtered through our client’s ops and marketing team. We also worked closely with our client’s Product Owner, taking on recommendations based on customer interactions and a greater understanding of customer pain points.

With each piece of qualitative data, we redesigned the key screens that catered to the evolving needs of the customer’s system, progressively increasing information as per the future business requirements. Features were designed to help the customer manage numerous equipment across multiple sites. We also assembled unique metrics which are both relevant and actionable for different personas. Data and KPIs matching with the business key value proposition were prioritised, as was a page which enabled users to track the equipment onboarding once the sensor gets installed.

From setting up the UI visualisation platform to building the underlying CI/CD pipelines, to integrating new ML tools and security measures, our team used agile development and UX principles to move away from technology-driven project design. This approach benefited the project for a number of reasons: we had complete visibility of the project from start to finish; more time to focus on building new features specific to customer feedback; and we could make informed decisions using specific sets of data.

One such feature was the introduction of a tracking system for oil samples. This system identified when a sample needed to be taken, whether the sample provided our client the right information and did it make sense when compared with other data already in the AI/ML model. This functionality was reflected on the UI and flagged whether the sampling process was running smoothly or needed to be changed. We also introduced checks and balances to ensure data was collected on a regular basis, with notifications sent directly to the app and customer email.

‘One team, One Objective’

The GlobalLogic team supported development and testing of AI/ML models, performed data connection, ingestion and transformation across multiple customer assets at scale, throughout the project. We also provided DevOps, QA and Test Automation leadership to promote transparency and cross-collaboration between our client (IT, Product and Business teams) and other stakeholders like Microsoft. This helped spearhead the project without segregating ownership and was key for creating ‘A Single Focal Effort’ that generated business value.

Whilst we worked alongside inhouse dev teams, this project sought help integrating with third party applications and their providers into one cohesive UI visualisation platform. This project has demonstrated how we can gain huge efficiencies by adopting modern ways of working and cross continent collaboration by leveraging Agile and DevOps principles, knowledge management. The most important factor that contributed to the success is the trust and transparency we have been able to develop with all stakeholders.

Summary: Moving from time-based to condition-based maintenance

Not only did we transform operations through intelligent lubricant oil condition monitoring, the AI/ML model provided real-time insights at the fingertips for industrial companies to optimise equipment health, lower maintenance costs, and increase operational efficiency.

This is how we moved from time-based maintenance to condition/health-based maintenance in summary:

- We followed a customer-centric approach to evolve the service from the MVP phase conducted by the research team of energy company to a scalable digitally enabled solution in the form of a responsive application delivering real-time insights.

- Build less, differentiate more: Our strategy enabled the service to be delivered in a way the most useful features can be identified (as per the customer’s need), prioritised, and delivered.

- Reduce time to market: We used a customer-centric approach by integrating user research and testing into agile development and overhauled the service. As a result the created solution matches the customer’s needs and expectations.

- Data-driven experience: We implemented an AI/ML model to collect quantitative data for business KPIs and user behaviour. Analytics data started providing us with actionable insight that helped us define a mindset that every decision should be data-driven.

For our client, the solution has helped gain new revenue from existing and new customers and sectors, upselling lubricants, bundling with existing and future services.

Client quote – Venture Lead of the Business

“I have been thoroughly impressed by GlobalLogic’s technical competence especially in Industrial IoT space where they worked collaboratively with our teams to create a great product which our customers love. GlobalLogic helped us transform our vision for the Condition based monitoring app into a reality by facilitating the design, development and roll out to multiple Industrial customers. The application greatly helped in reducing unplanned downtime, optimise performance, extend equipment life and improve Utilisation and increase productivity.”

Related Content

Case StudiesGlobalLogicHitachi Aqua-Tech Engineering Leverages GlobalLogic’s Digital Expertise ...

Industrial and Energy Case StudiesGlobalLogic

Case StudiesGlobalLogicEmpowering Hitachi Rail’s Digital Factory with Private 5G Networks for ...

Transformation AdvisoryTransformation Execution and GovernanceCommunications and Network ProvidersIndustrial and Energy Case StudiesGlobalLogic

Case StudiesGlobalLogicFlexware: Building a Culture of Product Innovation in a Service Company

This collaboration aimed to enhance its user experience, efficiency, reliability, and market fit.

Product and UI/UX DesignTransformation AdvisoryUser and Market ResearchIndustrial and Energy Get in touch

Get in touchLet’s start engineering impact together.

Join the world’s largest and most innovative companies in making GlobalLogic your trusted digital engineering partner.

How can I help you?

How can I help you?

Hi there — how can I assist you today?

Explore our services, industries, career opportunities, and more.

Powered by Gemini. GenAI responses may be inaccurate—please verify. By using this chat, you agree to GlobalLogic's Terms of Service and Privacy Policy.